Navigate Hard Surface with Confidence: Komatsu Undercarriage Parts Option Guide

Navigate Hard Surface with Confidence: Komatsu Undercarriage Parts Option Guide

Blog Article

Reliable Solutions: Undercarriage Parts for Heavy Machinery

When it concerns heavy machinery, the undercarriage is an important component that commonly identifies the overall effectiveness and efficiency of the equipment. Quality undercarriage parts play a substantial function in making sure the smooth operation and longevity of hefty machinery. From excavators to dozers, each item of devices depends greatly on its undercarriage to withstand tough working conditions. Wear and tear are inescapable, leading to potential problems that can prevent performance and rise upkeep expenses. In this conversation, we will certainly check out the importance of buying top-notch undercarriage parts, typical wear challenges encountered by hefty machinery drivers, the advantages of prompt replacements, standards for choosing reputable distributors, and important upkeep suggestions to expand the life expectancy of undercarriage elements.

Value of Quality Undercarriage Parts

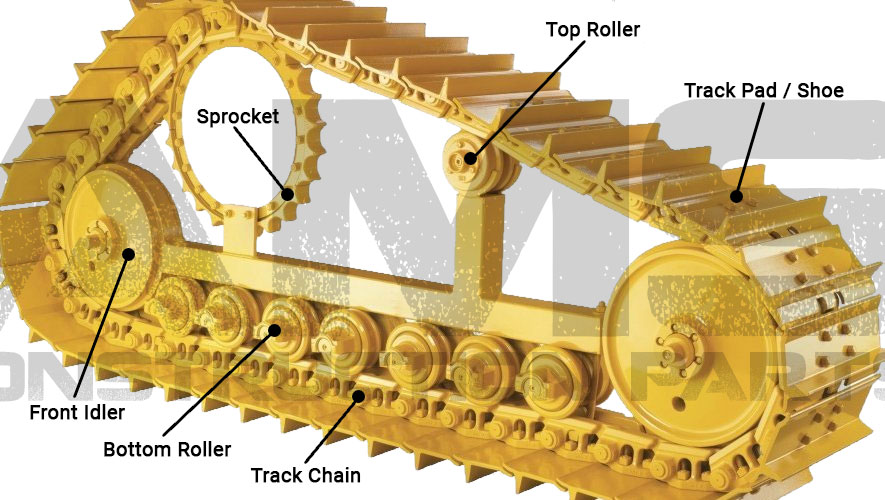

Quality undercarriage parts are essential parts in guaranteeing the resilience and performance of hefty equipment. The undercarriage of tools such as excavators, excavators, and track loaders plays a crucial duty in sustaining the machine's weight, providing stability on different terrains, and soaking up the influence of unequal surfaces. By buying top notch undercarriage components, operators can considerably extend the life expectancy of their machinery and decrease the danger of unexpected break downs.

One secret benefit of using quality undercarriage components is the enhancement of overall maker efficiency. Sturdy tracks, rollers, gears, and idlers reduce rubbing and ensure smoother activity, ultimately causing raised performance and performance on job sites. Trustworthy undercarriage components minimize downtime for maintenance and fixings, permitting operators to optimize their functional hours and job due dates.

Typical Undercarriage Use Problems

Advantages of Timely Replacement

One trick advantage of prompt undercarriage component replacement is boosted equipment uptime. By replacing worn components prior to they fail, the danger of unexpected failures is decreased, decreasing downtime for repairs and maintenance. This positive method not just keeps the hefty equipment functional yet likewise prevents prospective damage to other parts that could arise from a falling short undercarriage.

Additionally, changing undercarriage components without delay can boost overall productivity. A properly maintained undercarriage makes sure optimal machine performance, enabling smoother operation and greater efficiency in finishing jobs. This, in turn, results in increased job website performance and expense financial savings by avoiding interruptions and hold-ups brought on by underperforming equipment. For that reason, buying timely undercarriage part substitute is an aggressive strategy that settles in terms of boosted efficiency and minimized functional expenses.

Picking the Right Undercarriage Provider

Selecting the appropriate link undercarriage vendor is an essential choice that considerably impacts the performance and upkeep of hefty equipment. When picking a distributor for undercarriage components, several aspects must be thought about to guarantee optimum effectiveness and cost-effectiveness. A provider that provides a large selection of undercarriage parts for numerous heavy equipment brands and designs can be advantageous as it gives more options to meet specific demands.

Balancing cost-effectiveness, reliability, and quality is crucial when picking the best try this website undercarriage distributor for hefty equipment. By very carefully reviewing these variables, you can choose a supplier that fulfills your needs and adds to the effective efficiency and upkeep of your hefty equipment.

Maintenance Tips for Extended Life-span

To guarantee an extensive lifespan for hefty equipment undercarriage components, implementing an aggressive upkeep regimen is necessary. Investing in high quality undercarriage parts from respectable providers is just as essential for guaranteeing longevity. By adhering to these upkeep pointers diligently, hefty equipment owners can enhance the efficiency and sturdiness of their undercarriage parts, ultimately decreasing downtime and operational costs.

Final Thought

In conclusion, top quality undercarriage components are important for the reliable operation of heavy machinery. Choosing a reputable supplier and adhering to proper maintenance practices are crucial to guaranteeing the expanded life-span of undercarriage components.

Too much wear and tear on undercarriage parts of hefty machinery can lead to considerable operational obstacles and increased maintenance expenses. Normal inspections, correct maintenance, and prompt substitutes of worn undercarriage components are important to minimize these usual wear issues and make sure the optimum performance of heavy equipment.

A vendor that uses a broad choice of undercarriage get more parts for various hefty equipment brands and models can be beneficial as it supplies more options to satisfy details demands.

By adhering to these upkeep ideas diligently, heavy equipment proprietors can enhance the efficiency and toughness of their undercarriage parts, ultimately reducing downtime and functional prices.

Report this page